In the era of hyper-scale digitalization and urgent sustainability mandates, energy management in critical infrastructure has transcended simple billing. It is now a pivotal factor in operational efficiency, stability, and achieving net-zero goals. The new battlefield for operational excellence is precision energy intelligence.

At our core, we believe that the journey to a truly green data center, smart factory, or low-carbon building begins with the quality and granularity of measurement.

We recently executed three major energy monitoring upgrades that perfectly illustrate the nuanced demands across different sectors, cementing the role of the energy meter as the "Intelligent Neuron" of the entire power distribution system.

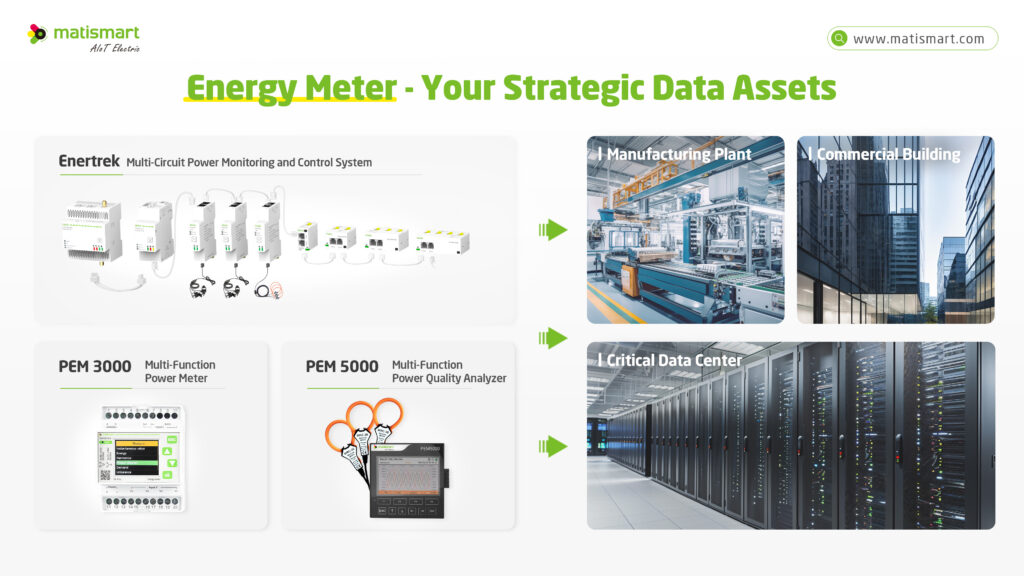

The New Paradigm: The Energy Meter as a Strategic Data Asset

Energy meters are no longer passive counting devices. They are the “Sensing Layer”—the fundamental source of data that feeds every smart system, from Building Automation Systems (BAS) to Enterprise Energy Management Systems (EEMS).

Our practical experience across diverse high-demand environments shows a clear divergence in measurement requirements, all aimed at turning raw energy consumption into actionable intelligence:

Unpacking the Toolkit: Three Pillars of Precision Measurement

To meet these varied needs, the field of power metering relies on three specialized instrument categories—each playing a distinct, vital role in the smart grid architecture.

1. 🔍 The "Physician": High-End Power Quality Analyzers (PQA)

Role: The system's diagnostic tool, ensuring the health and compliance of the electrical supply.

Strategic Impact: PQAs are designed to capture transient, invisible disturbances like voltage sags/swells, harmonics, and unbalance. They provide millisecond-stamped waveform captures, essential for root cause analysis of equipment malfunction or unplanned downtime.

Case in Point (Critical Data Center): By deploying a PQA on the main utility incoming lines, the facility gains an automated "electrical health report." This real-time analysis detects anomalies and provides forensic data that allows engineers to quickly determine if a critical event originated from upstream utility switching or internal load dynamics, significantly enhancing power supply resilience.

e.g., PEM5000 Multi-Function Power Quality Analyzer

2. 📊 The "Accountant": High-Accuracy Multifunction Energy Meters

Role: The distribution layer's financial tool, transforming power consumption into traceable cost centers.

Strategic Impact: These meters offer certified, high-accuracy measurement (Class 0.5S or better) of all essential parameters (kWh, kVArh, PF, Harmonics). They are the bedrock for cost allocation, efficiency metrics (like PUE), and regulatory reporting.

Case in Point (Advanced Manufacturing Plant): The adoption of the PEM3000 meters at main distribution panels enables true segmented energy accounting. Management can now correlate energy consumption with production batches or specific work shifts, identifying inefficiencies not just in equipment but in operational processes. The built-in harmonic monitoring is crucial for preventative maintenance of large industrial loads.

e.g., PEM3000 Multi-Function Power Meter

3. 🌐 The "Explorer": Modular Multi-Circuit Monitoring Systems

Role: The end-point density multiplier, rapidly expanding the measurement network.

Strategic Impact: The Modular Multi-Circuit Monitoring System addresses the pain point of branch circuit monitoring—high installation costs, limited space, and the necessity of scheduled shutdowns. These systems utilize modular, bus-based architectures for quick, plug-and-play expansion, achieving high-density submetering with minimal disruption.

Case in Point (Educational/Commercial Building Complex): Facing stringent constraints on downtime and physical space, a system allowed for the non-disruptive installation of metering across dozens of branch circuits in a matter of hours. This immediately enabled floor-by-floor and use-case-specific energy tracking, providing the facility team with the granular data needed for targeted energy reduction efforts.

e.g., Enertrek Multi-Circuit Power Monitoring and Control System

The Operational Edge: Delivering Agility and Scalability

In every successful infrastructure upgrade, the choice of the measuring device is complemented by a solution that is Agile, Quick, Flexible, and Scalable.

- Agile & Quick: Minimizing installation time is key. Quick-connect systems (like RJ12 bus-based wiring) allow for two-hour installations where traditional methods might take days, dramatically reducing the cost and risk of downtime.

- Flexible: Compatibility with various Current Transformers (CTs)—split-core, Rogowski coil, 5A—ensures the system can be deployed without complex re-engineering.

- Scalable: The measurement entry point must be lightweight and easily expandable. Adding a new load or circuit should be as simple as plugging in a new module, with automated node recognition at the platform level.

📈 Conclusion: Measurement is the Foundation of Digital Transformation

Digital transformation in energy is not about "going to the cloud"; it is about optimizing business decisions. For mission-critical data centers, the decision is "How do we prevent the next event?" For factories, it's "Where is the highest energy waste per unit?"

The Power Quality Analyzer, the Multifunction Meter, and the Modular Monitoring System are not mere accessories. They are the essential foundation upon which all successful energy efficiency, sustainability, and operational excellence programs are built. When every kilowatt-hour becomes traceable, the era of truly intelligent energy management will have arrived.